Understanding Type 5/6 Disposable Coverall Certifications

In hazardous environments, the right protective clothing is essential for safeguarding workers against a wide range of risks. From chemical splashes to airborne particles, the threats faced in industrial, medical, and other high-risk settings necessitate the use of specialised garments that provide reliable protection. Among these, Type 5/6 disposable coveralls are particularly valued for their versatility and effectiveness in guarding against both solid and liquid hazards.

Type 5/6 disposable coveralls are widely used across various industries, including pharmaceuticals, manufacturing, and construction, where the risk of exposure to hazardous materials is prevalent. However, understanding the various certifications and standards that these coveralls must meet can be challenging. This knowledge is crucial not only for compliance but also for ensuring that the chosen protective clothing provides the necessary level of safety for the task at hand.

In this article, we will explore the different certifications and standards associated with Type 5/6 disposable coveralls, explaining what they mean and why they matter, so you can make informed decisions when selecting the appropriate protective gear for your needs.

What Are Type 5/6 Disposable Coveralls?

Type 5/6 disposable coveralls are a category of personal protective equipment (PPE) designed to protect the wearer from hazardous substances in the form of solid airborne particles and light liquid sprays. Specifically, Type 5 coveralls protect against hazardous dry particles, while Type 6 coveralls offer protection against light liquid splashes. These coveralls are typically made from lightweight, non-woven materials that offer comfort and protection, making them suitable for extended wear in challenging environments.

These coveralls are commonly used in industries where workers are exposed to various airborne and liquid hazards. For instance, in the pharmaceutical and medical sectors, Type 5/6 coveralls are used to protect against dust, powders, and biological agents. In the construction and manufacturing industries, they are employed to safeguard workers from chemical splashes and dust particles. Additionally, they are crucial in asbestos removal, where the risk of inhaling harmful fibres is high.

The importance of certifications for Type 5/6 coveralls cannot be overstated. These certifications ensure that the coveralls meet specific safety standards, providing the necessary protection for workers in hazardous environments. Compliance with these standards is not just a legal requirement but also a vital aspect of workplace safety. By understanding and adhering to these certifications, employers can ensure that their workers are adequately protected, reducing the risk of injury and illness.

Learn more: Type 5/6 Disposable Coveralls: A Versatile Solution for Multiple Industries

Understanding the Certifications and Standards

Certifications play a critical role in ensuring that personal protective equipment (PPE) meets the necessary safety and performance standards. In hazardous environments, where workers are exposed to potentially life-threatening risks, the reliability of protective gear is paramount. Certifications serve as a guarantee that the equipment has been rigorously tested and proven to provide the required level of protection. For employers, adhering to these standards is not only a matter of regulatory compliance but also a crucial step in safeguarding the health and safety of their workforce.

When it comes to Type 5/6 disposable coveralls, several key certifications are particularly relevant. Each certification focuses on a specific aspect of protection, from safeguarding against solid particles to ensuring resistance to chemical splashes. Understanding these certifications is essential for selecting the right coveralls for the job, ensuring that workers are adequately protected against the specific hazards they may encounter.

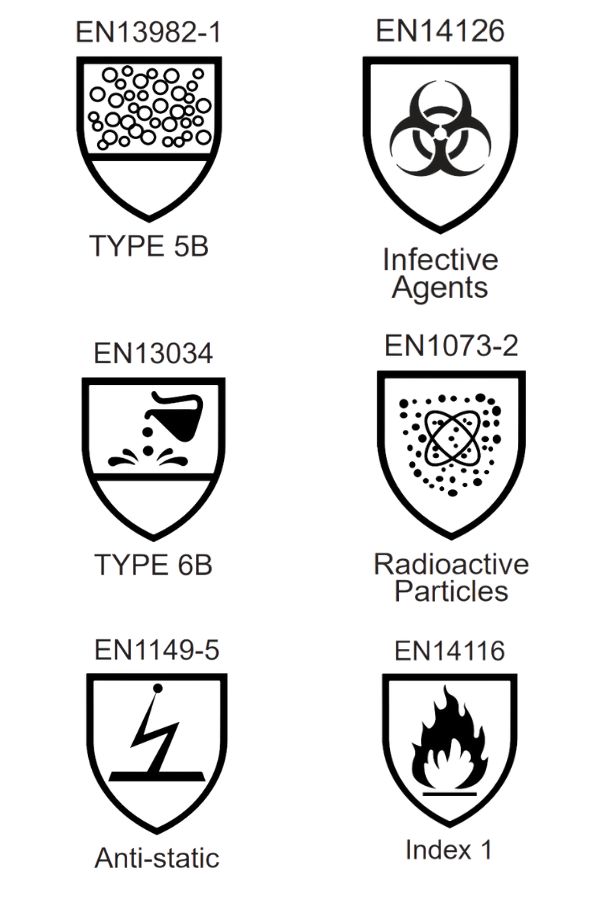

The key certifications related to Type 5/6 disposable coveralls include:

- EN 13982-1: This certification pertains to protection against solid airborne particles, ensuring that Type 5 coveralls provide effective defence against hazardous dust and fibres.

- EN 13034: This standard relates to protection against light liquid chemical splashes, relevant to Type 6 coveralls.

- EN1149-5: Focused on anti-static properties, this certification is crucial in environments where electrostatic discharge could pose a risk.

- EN 14126: This standard ensures protection against infective agents, making it vital in medical and laboratory settings.

- EN 1073-2: This certification is concerned with protection against nuclear particles, specifically Class 1, offering defence against radioactive contamination.

- EN 14116: This standard ensures limited flame spread, providing essential protection in environments where fire hazards are present.

By familiarising yourself with these certifications, you can make informed decisions about the most appropriate Type 5/6 disposable coveralls for your specific needs, ensuring both safety and compliance.

EN 13982-1: Protection Against Solid Particles

EN 13982 is a standard that ensures protective clothing offers sufficient defence against solid airborne particles. Type 5 coveralls certified under this standard are designed to prevent hazardous dry particles, such as dust and fibres, from penetrating the fabric, thereby safeguarding the wearer from potential harm.

This certification is crucial in industries where exposure to airborne particles is a significant risk, as it ensures that the coveralls provide an effective barrier, protecting the wearer’s respiratory system and skin from dangerous substances.

Industries/Situations Where Critical:

- Asbestos removal

- Pharmaceutical manufacturing

- Construction sites with heavy dust exposure

Testing Method

Determination of inward leakage of aerosols & solid particles:

- Spray cabin filled with particles

- The test is performed by a real person, aims to simulate daily use

- Subject (real person) performs 3 exercises on a treadmill

- Particle inward leakage(IL) and total inward leakage(TIL) must meet test requirements

Recommended Coverall with EN 13982-1: Chemsplash Xtreme 50 SMS Coverall Type 5/6

EN 13034: Protection Against Liquid Chemicals

The EN 13034 standard certifies that Type 6 coveralls offer limited protection against light liquid chemical splashes. These coveralls are treated to resist penetration by low-risk chemicals, providing a temporary barrier that allows the wearer to avoid injury by removing the garment before the chemicals can cause harm.

This certification is particularly relevant in environments where the risk of chemical exposure exists but is not severe, making it suitable for industries that handle small quantities of chemicals or where accidental splashes are possible.

Industries/Applications Where Relevant:

- Chemical processing plants

- Laboratory environments

- Maintenance work involving light chemical handling

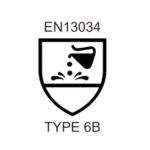

Testing Method

Determination of resistance to penetration by reduced liquid spray:

- 4 nozzles with general overspray of liquid without penetration on coverall

- Low surface tension of liquid sprays being tested on the whole garment to experiment saturation of the fabric

- Fabric, seams and joints being tested without pressurised liquid spray

- About 40% of the liquid spray is loaded onto the suit compared with Type 4 test

Recommended Coverall with EN 13034: Chemsplash Eka 55 Coverall Type 5B/6B

EN1149-5: Anti-Static Properties

EN1149-5 is a standard that ensures protective clothing has anti-static properties, which are crucial in environments where static electricity could pose a significant risk. This certification is particularly important for preventing static discharge that could ignite flammable substances or damage sensitive electronic equipment.

Coveralls certified under EN1149-5 help to dissipate static electricity safely, thereby reducing the risk of accidents in sensitive or hazardous environments.

Industries Where Essential:

- Petrochemical plants

- Electronics manufacturing

- Aerospace industry

Recommended Coverall with EN 1149-5: Chemsplash Cool 67 Coverall Type 5/6

EN 14126: Protection Against Infective Agents

The EN 14126 standard ensures that protective clothing provides a reliable barrier against infective agents, including bacteria, viruses, and other pathogens. Type 5/6 coveralls that meet EN 14126 certification are designed to prevent the penetration of biological hazards, making them essential in environments where there is a high risk of exposure to infectious materials.

This certification is vital for ensuring the safety of workers in settings where they might come into contact with dangerous pathogens, providing critical protection in a variety of high-risk environments.

Key Industries/Applications:

- Healthcare facilities

- Medical laboratories

- Pharmaceutical manufacturing involving biological materials

Recommended Coverall with EN 14126: Chemsplash Cool 67 Coverall Type 5/6

EN 1073-2: Protection Against Nuclear Particles

EN 1073-2 (Class 1) is a certification that ensures protective clothing offers protection against radioactive particles. Type 5/6 coveralls with EN 1073-2 certification are designed to shield the wearer from radioactive contamination by preventing particles from reaching the skin or being inhaled.

This standard is particularly important in environments where exposure to radioactive dust or particles is a concern, providing necessary protection in scenarios involving low levels of radiation.

Situations Where Crucial:

- Nuclear power plants

- Radiological research laboratories

- Medical facilities handling radioactive materials

Testing Method

Determination of inward leakage of aerosols & solid particles:

- The standard was developed to be applied in the nuclear industry with no protection against ionising radiation

- The test follows the same protocols as a Type 5 test with different judgment criteria

- 3 classifications indicate different protection level

Recommended Coverall with EN 1073-2: Chemsplash Xtreme 50 SMS Coverall Type 5/6

EN 14116: Limited Flame Spread (Index 1)

Protective coveralls certified under EN 14116 provide limited flame spread protection, classified under Index 1. This standard is crucial in environments where there is a risk of incidental flame exposure, ensuring that the garment will not ignite easily and will self-extinguish once the flame source is removed.

The limited flame spread protection is essential in industries where fire hazards exist, albeit not as the primary risk, offering an additional layer of safety for workers in potentially hazardous environments.

Applications Where Relevant:

- Oil and gas industry

- Welding operations

- Certain manufacturing processes with fire risk

EN ISO 14116 Flame Retardant Test

- To check whether the fabric/materials burn while contacting heat exposure

- To check whether the fabric stops flame spreading if burned

- Requirements for limited flame spread Index 1 including no spreading of the flame, no flaming debris, no afterglow, a hole may be formed

Recommended Coverall with EN 1073-2: Chemsplash Xtreme SMS 50 Flame Retardant Coverall Type 5/6

Choosing the Right Coveralls Based on Certification

Selecting the appropriate Type 5/6 coveralls requires careful consideration of the certifications that match the specific risks present in your job environment. Each certification is designed to protect against particular hazards, so it’s essential to understand which standards are relevant to your industry and the potential dangers your workers may face.

When choosing coveralls, start by assessing the job environment and identifying the primary hazards. For example, if workers are exposed to hazardous dust, the EN 13982 certification (Type 5) is crucial. If there’s a risk of chemical splashes, then coveralls with the EN 13034 certification (Type 6) would be more appropriate. Similarly, in environments where static discharge or biological hazards are concerns, the EN1149-5 or EN 14126 certifications would be vital.

Beyond identifying the relevant certifications, consider the specific conditions of your workplace. Factors such as the level of exposure, duration of wear, and the physical demands of the job should all influence your choice. Matching the coveralls’ certification to the specific risks in your environment is not just about compliance; it’s about ensuring the safety and well-being of your workers.

Factors to Consider:

- Job Environment: Type of industry, typical hazards present, and overall working conditions.

- Potential Hazards: Specific dangers like chemicals, particles, static, infectious agents, radiation, or flames.

- Industry Standards: Regulatory requirements and best practices for safety in your sector.

By carefully evaluating these factors and aligning them with the appropriate certifications, you can ensure that the protective clothing you select provides the necessary protection, ultimately contributing to a safer and more secure workplace.

Conclusione

Understanding the various certifications associated with Type 5/6 disposable coveralls is crucial for ensuring that your workers are adequately protected in hazardous environments. Each certification addresses a specific type of risk, whether it's solid particles, liquid chemicals, static discharge, or biological hazards. By familiarising yourself with these standards, you can make informed decisions that not only comply with industry regulations but also provide the highest level of safety for your team.

Selecting the right PPE is not just a matter of compliance; it’s a commitment to the health and safety of your workforce. By carefully considering the job environment, potential hazards, and relevant industry standards, you can match the protective clothing to the specific risks your workers face, thereby minimising the likelihood of accidents and ensuring a safer workplace.

As you assess your PPE needs, we invite you to explore Chemsplash’s comprehensive range of Type 5/6 disposable coveralls. Our products are designed to meet the highest standards of protection, offering you peace of mind and ensuring the safety of your team in even the most challenging conditions.

L'indirizzo e-mail non può essere pubblicato. I campi obbligatori sono contrassegnati*.